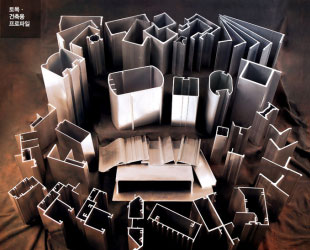

Extrusion mold

KPTU has accumulated 20 years of experience, technology and high-value-added molds for domestic and overseas markets. We are striving to foster R & D and hi-tech technology to meet the rapidly changing market trend.

KPTU supports batch work from product development stage (product design and Shape drawing) to mold design production and production, and designers can produce fast and accurate data by using functions such as 2D and 3D to produce the best mold .

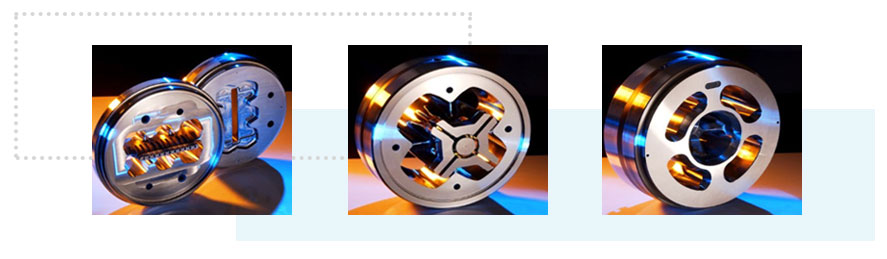

Extrusion mold

The extrusion mold is a tool for heating and pressing aluminum billet (steel) to a constant temperature to create a certain shape.

In the case of industrial profiles requiring high strength, the number of cores increases, however, KPTU designs and manufactures competitive and unique extrusion molds using JA Tool Design technique. Compared to other companies, it has high competitiveness.

Our Technology

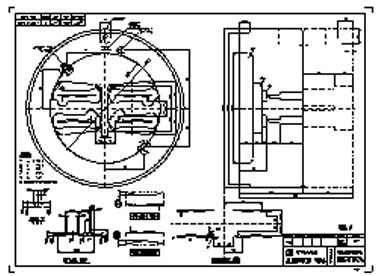

Dies Production range 140~ 900 350~400set/month

Maximum manufacturing error 0.025mm

Defect rate less than 0.05%

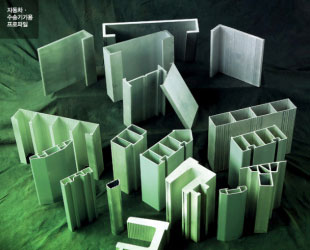

Extrusion Dies

Design and manufacture advanced profiles and industrial molds using CAD / CAM 3D system

Step 1

Design

Step 2

Cutting material

Step 3

Processing

Step 4

Discharge processing

Step 5

Wire discharge

Step 6

Mold